RAPID PROTOYPING

In order to ensure the functionality of a design prior to production, we provide our clients with high-quality prototypes. We use a combination of solutions to include fused deposition modeling (FDM), RTV molding and CNC machining.

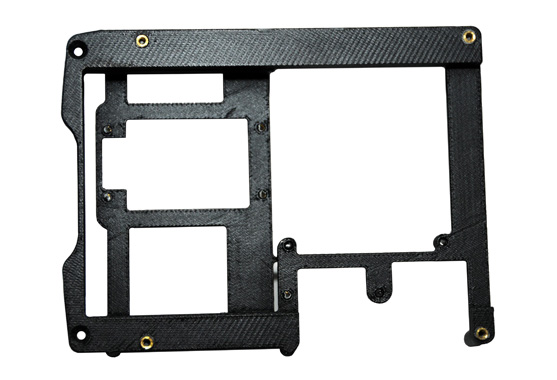

Our designers and engineers work together to model, print, program, machine and assemble your prototype, all under one roof. Prototypes can be post-processed with Class-A surfaces, ultrasonically welded, epoxy bonded, painted, screen printed and even fiber reinforced to mimic a composite structure.

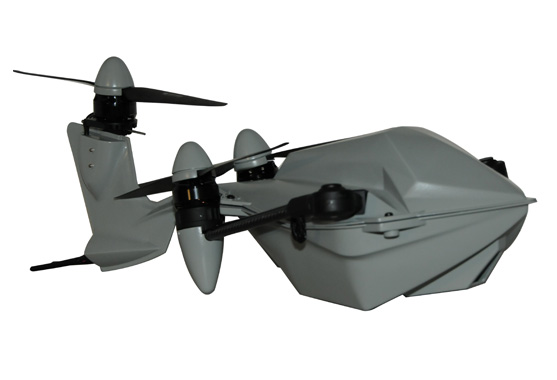

Rapid Composites specializes in fabricating highly complex and precision rapid prototypes that can even fly! Our proprietary reinforcing techniques are second to none. Prototypes can be tested with actual hardware allowing us to identify problem areas before entering into tooling and production phases.