MATERIAL SCIENCE

Area of Focus:

• Thermoplastic Composites

• EMI/RFI Shielding

• Thermally Conductive Materials

• Non-Conductive Materials

• Rapid Cure Composites

• Compounding/Hybridization

• Continuous Fiber Molding

We have materials that are up to two times more thermally and electrically conductive than copper. Conversely, we also work with dielectric and radiolucent materials. There are literally thousands of options and combinations available. Automated molds are made from aluminum or steel depending primarily on processing temperature requirements. Aluminum and steel have shot lives of 5,000 and 50,000, respectively. These molds often cost 60% to 70% less than conventional processes like injection molding or die-casting.

THERMOPLASTICS COMPOSITES

Compared to Metals:

• High Strength/Stiffness, Toughness

• Reduced Weight Low Coefficient of Thermal Expansion (CTE)

• Inherent Corrosion and Chemical Resistance

• Increased Part Function via Part Consolidation

• Reduced Secondary Operations

• Styling Freedom/Contoured Shapes

• Inexpensive Tooling

Compared to Thermoset Composites:

• No Need For Controlled Storage/Unlimited Shelf Life

• Significantly Faster Cycle Times (lower mfg. cost)

• Environmentally Sound and Recyclable

• Can be Re-processed – Reduced Scrap

• Superior Toughness

• Standard Polymers:

Standard Polymers:

• TPU

• PC

• PET

• PET-G

• PA-11, 12, 6, 6/6

• PBT

• PPS

• PEI

• PEEK

• PEK

• LCP

EMI/RFI SHIELDING

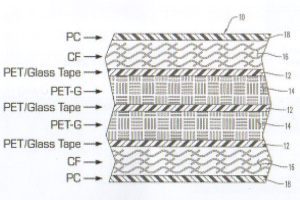

Rapid Composites can incorporate precision-expanded metals and foils to meet your exact requirements for shielding, electrical conductivity and thermal transfer properties. Our in-situlaminated shielding materials can be incorporated into the thermoplastic matrix, providing superior performance that does not flake off with time. This is an effective shield against EMI/RFI emissions. Formed from sheet metal, the shape, pattern and open areas are engineered to match the needs of your particular application. More than 35 different metals can be custom expanded to shield against specific wavelength spectrums. They can even be laminated, coated and plated. We offer some of the only composite structures capable of being soldered.

Our experience further extends into co-laminated, dielectrically insulated foils and flexible PCBs acting as conductive traces, thereby, eliminating point-to-point wiring connections. These materials wrap and conform to almost any shape. Designers are free to be creative with complex surfaced geometry.

Notable Advantages:

• High Electrical Conductivity

• High Thermal Conductivity

Expanded metal options that can be co-molded into our composite materials include the following:

• Al 1145

• Al 3003

• Al 1100

• Brass 260

• Brass 70-30

• Brass 80-20

• Brass 85-15

• Bronze 90

• Cadmium

• Copper

• Gold

• Hastiloy X

• Haynes 214

• Inconell 600

• Iron

• Lead

• Magnesium

• Molybdenum

• Ni 201

• Nickel

• Ni 899L

• Niobium

• Palladium

• Platinum

• Platinum Clad Niobium

• Silver

• SS 304L

• SS 316L

• SS 444

• Steel 1008

• Tantalum

• Titanium

• Zinc 500

• Zirconium

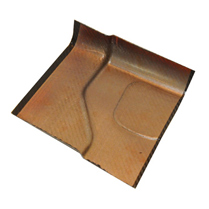

EMI/RFI SHIELDING EXAMPLES

THERMALLY CONDUCTIVE MATERIALS

Rapid Composites has the ability to design, tool, mold and safely post-process machine advanced thermally conductive components for a wide range of industries. Our battle proven solutions operate in the most extreme environments.

We have years of experience working with thermally conductive PITCH-based crystalline carbon fabrics, braids, chops and milled fibers. These materials are produced is a wide range of styles and are even available in unidirectional, biaxial and tri-axial forms. PITCH fabrics can be processed into composites for a variety of thermal and CTE-critical applications that require exceptional fatigue and frictional properties. These materials can be infiltrated with metals or polymers for optimized thermal and mechanical properties.

Thermally conductive discontinuous fibers are available is a free-flowing form that can be easily blended and compounded with most other materials.

Many of the materials utilized have a longitudinal thermal conductivity more than two times higher than copper at 900 W/mk, and a tensile modulus greater than 120Msi. Chopped fibers are also available in 1/2″ to 4″ lengths with a thermal conductivity of 350 W/mk to 900 W/mk varying by grade. These materials can also be mixed as a slurry with fibers isotropically oriented ensuring that conductivity will be equal in any direction.

Notable Advantages:

• Zero CTE

• High Thermal Conductivity

• High Electrical Conductivity

• Excellent Impact Resistance

NON-CONDUCTIVE MATERIALS

A great deal of emphasis is put on increasing the thermal and electrical conductivity while reducing weight.

Conversely, we are often asked to design components that require dielectric or radiolucent properties.

There are many suitable thermoplastic and thermoset composite materials available in both continuous and chopped fiber.

We routinely utilize e-glass materials for radome and antenna applications. Phenolic-based composites are often used for radiolucent applications.

Many of the fabrics and chopped fiber can be molded with PPS or PEEK to provide superior temperature resistance and increased impact strength.

Notable Advantages:

• Low CTE

• Low Dielectric Constants of 2.5 or less can be achieved

• Thermal Insulating Properties

• Excellent Impact Resistance

COMPOUNDING AND HYBRIDIZATION

Rapid Composites has the ability to combine materials in unique custom ways to meet the most challenging demands.

• Polymerization Research

• Hybrid Development

• Compounding

• Consolidation

• Hydrocarbon Chain Modification